Condition Monitoring

System Upgrades

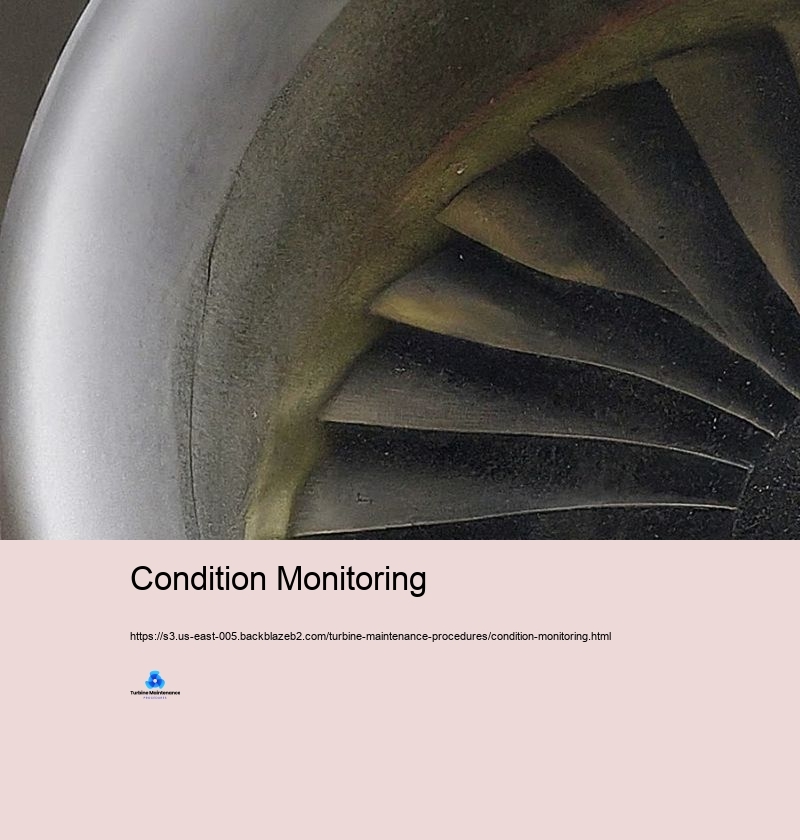

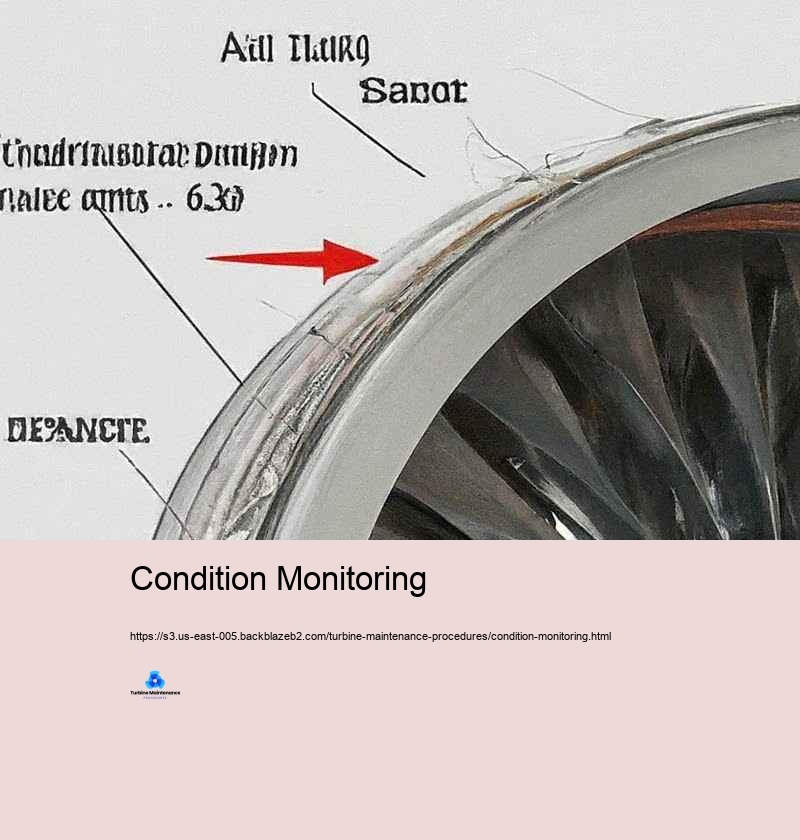

Turbine maintenance is a crucial aspect of power generation, industrial procedures, and different other applications where wind turbines play a vital function. Right maintenance ensures optimum efficiency, extends the life-span of the tools, and protects against expensive breakdowns. This introduction to turbine maintenance uncovers the essential principles and techniques important for protecting these complex tools correctly. At its core, turbine maintenance pertains to protecting the security and performance of the turbine system. Wind generators, whether vapor, gas, or hydraulic, are innovative items of devices that convert power from a fluid (vapor, gas, or water) right into power. The high-speed turning, extreme temperature levels, and anxiety associated with their treatment make routine and extensive maintenance crucial. Among the fundamental principles in turbine maintenance is precautionary maintenance. This favorable method entails regularly set up inspections, cleaning up, and small mendings to prevent major failings prior to they take place. Preventive maintenance frequently contains tasks such as lubricating bearings, checking and adjusting clearances, analyzing blades for wear or damages, and monitoring vibration degrees. By addressing little problems early, preventative maintenance can considerably reduced the risk of devastating failings and broaden the turbine's useful life. Condition-based maintenance is one more crucial idea that has obtained importance with the development of ingenious security innovations. This strategy relies upon real-time information from sensing units and keeping track of systems to establish when maintenance is required. Criteria such as vibration, temperature level, stress, and oil trouble are continually monitored. When these criteria vary regular ranges, it shows potential concerns that need rate of interest. Condition-based maintenance allows a lot more targeted and reliable maintenance tasks, minimizing unwanted downtime and making best use of source appropriation. Anticipating maintenance takes condition-based maintenance an activity even more by using data analytics and expert system solutions to predict when failings are likely to take place. By analyzing historical information and current operating problems, anticipating maintenance systems can projection possible issues before they reveal as apparent troubles. This method permits maintenance groups to strategy treatments at one of the most beneficial times, lowering disturbance to procedures and optimizing the efficiency of maintenance tasks. Placement is a vital practice in turbine maintenance. Correct placing of the turbine shaft with the generator or driven gadgets is crucial for smooth treatment and durability. Imbalance can produce severe vibration, sped up wear of bearings and seals, and minimized performance. Normal placement checks and adjustments, typically making use of laser positioning tools, are a common element of turbine maintenance routines. Stabilizing is one more crucial component of turbine maintenance. The high-speed rotation of turbine components shows that also little discrepancies can reason considerable vibration and put on. Dynamic stabilizing of rotors and impellers is accomplished to warranty smooth procedure. This procedure requires including or eliminating small amounts of weight at specific points to accomplish optimum balance. Routine resonance evaluation helps acknowledge inequality concerns early, allowing timely renovations. Assessment and cleaning up of turbine blades are essential maintenance practices. Blades can deal with different worries such as erosion, rust, fouling, or physical damages. Normal examinations, frequently making use of borescopes or other non-destructive testing techniques, assistance identify these problems. Cleansing of blades, which may include chemical cleaning or mechanical methods like grit blasting, aids keep aerodynamic effectiveness and stays clear of performance damage. Lubrication administration is a critical element of turbine maintenance. Correct lubrication of bearings, devices, and other relocating parts is crucial for minimizing rubbing and use. This involves not just assuring a sufficient supply of lubricant yet also monitoring its top quality. Oil evaluation is an usual practice that help identify impurities, use pieces, and modifications in oil structures that can suggest developing issues in the turbine system. Seal maintenance is another vital approach. Condition Monitoring Seals prevent leak of working liquids and lubricating materials, and their failure can cause substantial efficiency losses and prospective security hazards. Regular evaluation and substitute of seals, specifically in high-pressure or high-temperature locations, is a basic part of turbine maintenance regimens. Control system maintenance is substantially crucial as wind generators become a great deal even more electronic and electronically controlled. This includes routine checks and calibration of noticing systems, actuators, and control shutoffs. Software program application updates and cybersecurity activities are additionally important aspects of modern turbine control system maintenance. Safety and security is exceptionally crucial in all turbine maintenance tasks. Generators entail high powers, severe temperature degrees, and possibly unsafe products. Rigid adherence to safety and security procedures, consisting of lockout/tagout procedures, restricted area entry procedures, and correct use personal protective devices (PPE), is vital. Safety and protection training and regular correspondence course for maintenance workers are important approaches in turbine maintenance programs. Documentation and record-keeping are crucial methods in turbine maintenance. Extensive logs of all maintenance jobs, consisting of examinations, repair services, and component substitutes, offer useful historical information for fad assessment and future maintenance prep work. Lots of companies currently make use of electronic maintenance management systems (CMMS) to improve this treatment and help with info analysis. Training and capability growth of maintenance employees is a continuous strategy in turbine maintenance. As turbine modern technologies advancement, maintenance techniques and devices also development. Regular training programs make sure that maintenance workers are current with one of the most as much as date maintenance practices, analysis tools, and safety and safety procedures. Ecological factors to consider are ending up being progressively important in turbine maintenance. This includes appropriate managing and disposal of unsafe items like used oils and cleansing chemicals. Lots of maintenance techniques now concentrate on decreasing environmental impact while guaranteeing ideal turbine effectiveness. Turbine maintenance is a complicated and diverse field that combines mechanical, electrical, and dramatically, digital competence. The critical principles of preventative, condition-based, and preparing for maintenance create the framework of contemporary turbine maintenance techniques. Practices such as placing, stabilizing, blade examination and cleaning up, lubrication monitoring, and control system maintenance are vital for guaranteeing the stability, performance, and durability of turbine systems. As turbine advancements continue to develop, maintenance practices will absolutely likewise advance, including new modern technologies and methods to please the problems of maintaining these essential tools in an ever-changing energy landscape.